EMS System – Energy Mornitoring system

What is Energy Management System(EMS)?

Energy Management System (EMS)

The Energy Management System (EMS) is a system that allows users to monitor energy consumption across the entire production line of a factory. The primary goal of the EMS model is to optimize energy consumption (electricity, water, gas, etc.)

SEEG Provides

Through the EMS, SEEG, with its team of experienced engineers, will provide technological solutions to help factories increase production efficiency on each production line, reduce production costs as well as energy usage costs, and contribute to minimizing CO2 emissions for sustainable development

Comprehensive Solution

SEEG offers a comprehensive solution including consulting services, surveys, design, and installation from hardware to software, enabling enterprises and industrial plants to monitor, measure, and manage energy (EMS), thereby enhancing their competitive capacity.

Why is it necessary to digitize energy management through EMS?

EMS brings many important benefits to industrial plants, including:

- Reducing energy costs

- Enhancing operational efficiency

- Decreasing emissions and environmental impact

- Improving maintenance and equipment lifespan

- Supporting decision-making

- Increasing competitive capacity

- Ensuring compliance with regulations and standards

Reducing Energy Costs

Enhancing Operational Efficiency

Decreasing Emissions And Environmental Impact

Improving Maintenance And Equipment Lifespan

Supporting Decision-Making

Increasing Competitive Capacity

Ensuring Compliance With Regulations And Standards

MODULE FEATURES

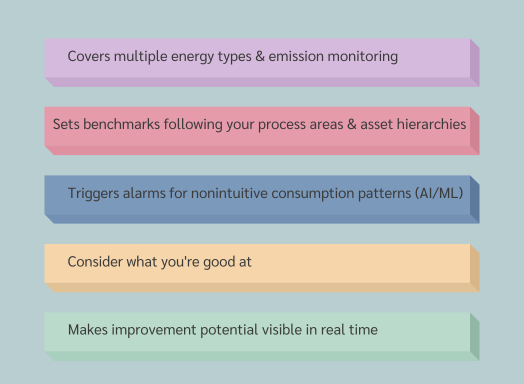

Monitoring & Reporting

- - Set benchmarks following your industrial processes areas and asset hierarchies, automate reporting against targets

- - Trigger alarms for non-intuitive consumption patterns

- - Make savings potential visible in real time

- - Facilitate ISO 50001 certification

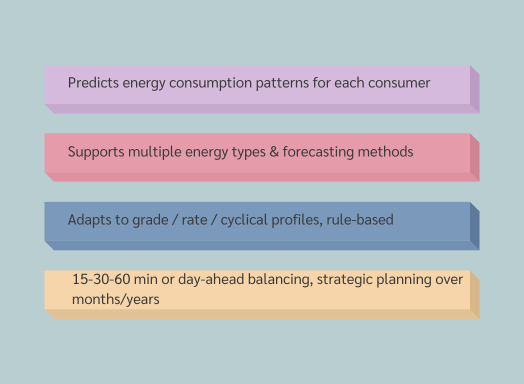

Forecasting & Planning

- - Predicts energy consumption of entire plant and process areas based on production plans

- - Calculates corresponding energy supply schedules to avoid penalties and gets the best price

- - Make savings potential visible in real time

- - Supports 15-30-60 min periods for electricity procurement

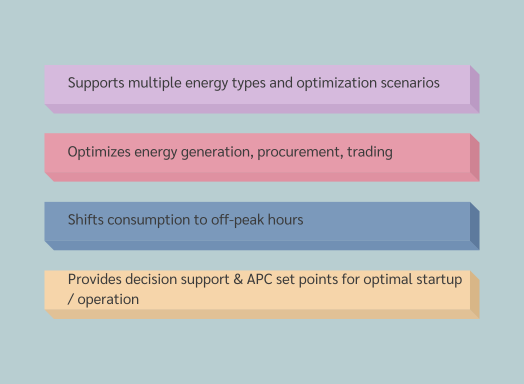

Energy Optimization

- - Energy demand: Suggestions of viable production schedule scenarios towards times of lower energy prices, or to avoid contractual power/energy limits

- - Energy supply: Suggestions of optimal use of energy resources to meet loads at minimum total cost. Particularly relevant when plant has access to multiple energy sources (e.g., Grid, On-site generation, energy storage, renewables)

- - Reduce up to 15% of energy cost depending on energy intensity, process flexibility and energy markets

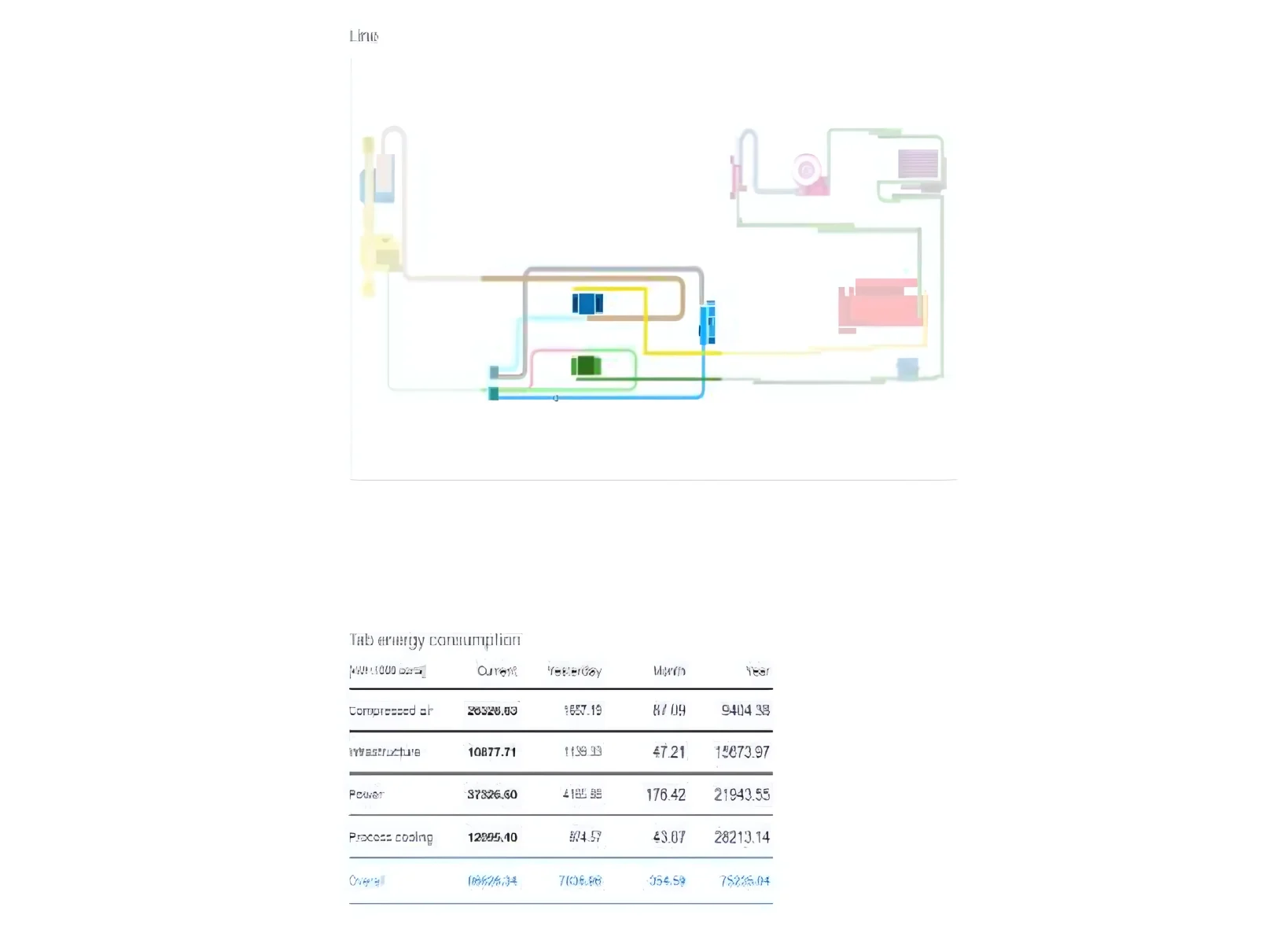

Monitoring Operating Data

Monitoring Operating Data

Allows real-time monitoring of energy parameters such as electricity, steam, oil consumption, gas consumption, etc. which supports operators or managers identify consumption levels and consumption norms for each product; Protect workers and equipment safety.

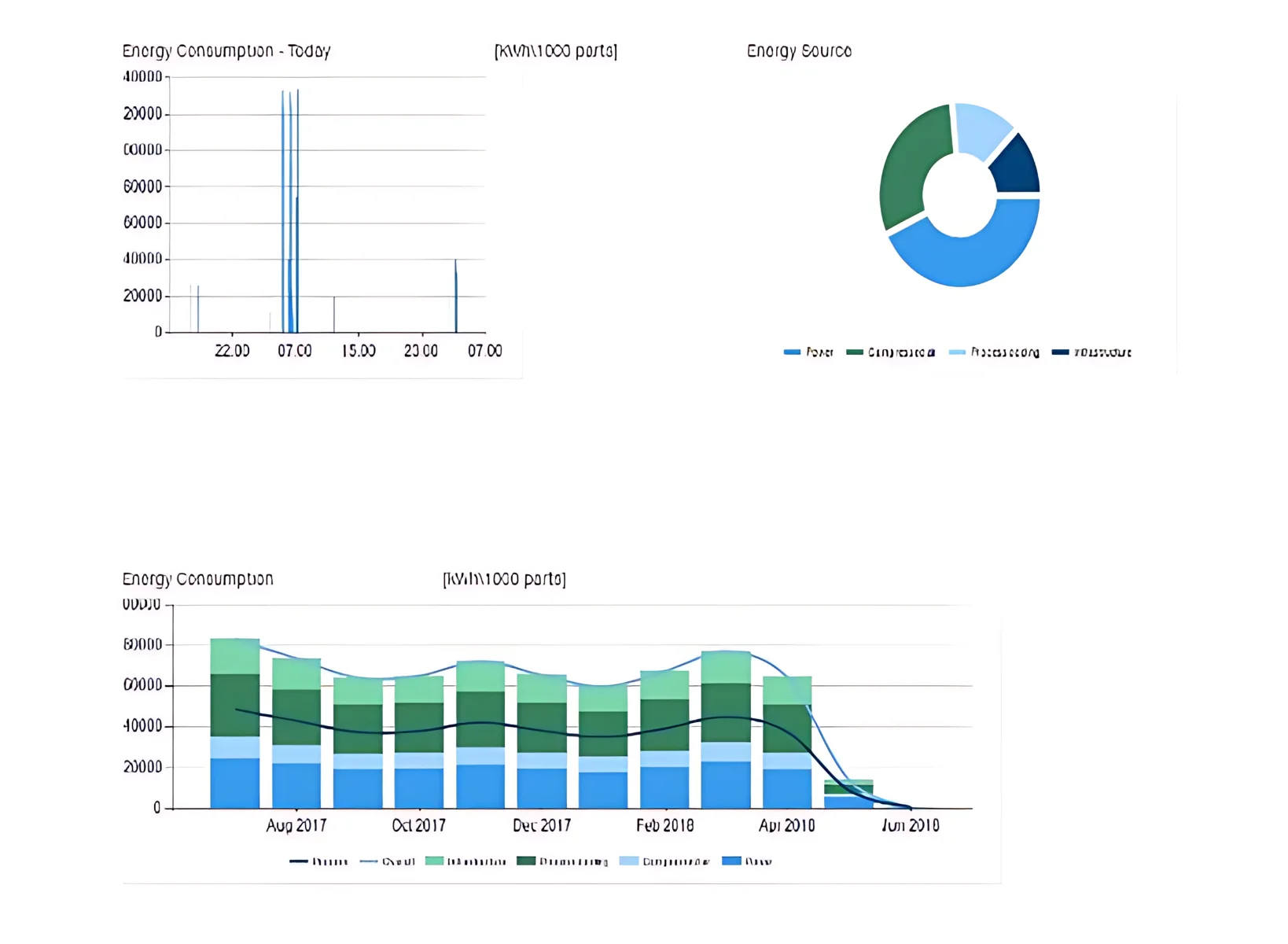

REPORT & DEMONSTRATE HISTORY DATA

Report & Demonstrate History Data

- - Report energy usage by hour, by shift, by day, month, year, etc.

- - Report calculating energy usage costs

- - Analytical reports such as loadmanagement reports, peak load reports, etc.

- - Able to select specific period tim

- - Export reports to pdf or excel fil

- - Report on price electricity costsaccording to EVN standards

Intergrating & Extending Functions

Able to integrate with DCS/SCADA systems or operate independently:

- The system can be integrated with the plant’s existing DCS/SCADA systems

- Operates as a standalone system

- Variable connection protocols with different field instruments from many different manufacturers

Module 1: Monitoring and Reporting

An online platform for monitoring, automated reporting against targets and decision support

- • Bring transparency over energy consumption and sustainability performance

- • Influence organization and routines around continuous improvement of energy efficiency

- • Achieve and maintain ISO 500001 certification

Module 2: Forecasting and Planning

Planning tools that forecast energy consumption & calculate the corresponding energy supply schedule to

- • purchase the right level of power in liberalized power market and minimize cos

- • Predict complex/variable energy demand with temporary peaks more accurate

- • Design the most effective production plan given power/energy constraints

Module 3: Energy Optimization

Holistic energy supply & demand optimization depending on your business objectives:

- • Minimize the total energy cost, reduce emission levels or maximize the total profit of the operations

- • Leverage process flexibility for peak shaving, load shedding, shifting production when energy is cheaper

- • Leverage flexibility in energy sources to enable effective energy procurement strategy

System Applications

Energy monitoring system brings safety, reliability, and efficiency to factories and enterprises of different sizes

A Successful Industrial Energy Management Strategy

A comprehensive energy monitoring solution (EMS) to deliver on sustainability targets and energy cost savings, engaging in cost reduction, energy efficiency and decarbonization measures toward Net Zero

CONTACT US

Contact SEEG now for comprehensive solution consulting to enhance efficiency and optimize your business!